Why you should choose a specialist longarm instead of a domestic machine on a frame

When quilters find it difficult to move a quilt around under a domestic machine to do free motion quilting they naturally try to find an easier solution!

It's really hard moving the bulk of the fabric and wadding under a small freearm. You continually have to move it to stitch a new area. Sometimes it gets stuck and then suddenly frees itself and before you know it you've got short stitches and long stitches and you're unpicking it because you don't want to ruin the end result which has taken you ages to piece. We've been there too.

You can watch our video of my experience trying to complete a Log Cabin quilt under my domestic machine here.

You could always use a "Quilt As You Go" method like Angela Walters shows here. However it still doesn't give you the freedom of longarm quilting and the playtime that you get. It's also a lot more of a faff! So if you're looking at making your quilt life easier a sitdown (stationary) or standup (moveable) quilt machine is going to make your quilting more creative and enjoyable.

Domestic machine on a fold up or permanent frame?

At shows you sometimes see frames with a domestic machine on it.

Whilst it initially sounds like a good idea right there are significant disadvantages to going this route.

Since I am in the position of having sold both domestic machine frame quilting systems and longarm purpose built systems I'll give you the lowdown on why a longarm that is built for purpose is going to always be the better choice.

|

| The Moxie 15" Longarm with Loft Frame |

|

| The Capri 18" Longarm with InSight Table for stitch regulated stitches |

1. Domestic machines - straight stitch versus zigzag

A domestic machine that does zigzag (swing needle system) is always going to be a compromise when it comes to doing a really nice straight stitch. The machine is designed to move the needle from side to side.

There is less movement, more precise stitches and when you start doing free motion quilting in all directions the result from a straight stitch machine is better.

Even if you put a straight stitch domestic machine on your frame it won't be setup for free motion quilting.

Do you know how to set the bobbin tension or top tension for free motion quilting? Are there lessons available by the supplier on how to do this? There are some key pointers that you may be able to get from YouTube but the key reason that you will never outperform a longarm is that Handi Quilter longarms are ONLY set up to do free motion quilting and the position of the hook and the needle is precisely set for this purpose. We explain why in point 2 below.

2. Machines set up for one purpose - longarm quilting!

3. Free arm space - If you start with 9" free arm space you'll have 5" of sewing space at the most!

If you put a domestic machines on a frame you end up with 5" or 7" of quilt space. You lose about 4" off any machine when you put a rail under the free arm and the wadding and fabric get rolled up as you progress through the quilt which takes up more and more space.

And it's not just about the distance front to back. The height of longarms that are built for quilting is so much more too, allowing space for the quilt to be quilted from start to finish with lots of space for movement. This shows how you can use a Little Foot frame to quilt even up to King Size with just 7' x 7' of space.

4. Rotary hook versus top loading bobbins and yes, bigger is better!

You may remember the old Singer machines with rotary hook bobbins. Well, those are the same kind of hook system that you'll find on our industrial quality longarm machines. We use them because they are a tried and tested accurate system but also can run at fast speeds. A domestic machine normally sews less than 1600 stitches per minute. Most will do 1100 stitches per minute or less. This is a result of a combination of the needle and bobbin case physical limitations and how the manufacturers design their machines (motor speed and swing needle design). Our machines sew between 1800 stitches per minute and 3100 stitches per minute. From a quilters point of view it means you're not continually wanting to sew faster than the machine!

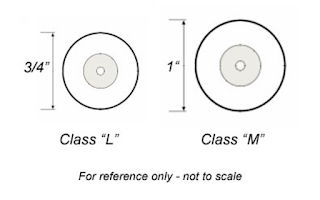

The M size bobbin allows you to quilt for longer so that you're not continually changing the bobbin as it runs out so much faster. For example, a prewound L bobbin from Wonderfil is 110 yards versus a huge 210 yards for the M bobbin!

5. Tension Adjustment

When we set up our longarm machines we adjust the bobbin first. We do what is called the "Bobbin Drop Test". You can see how to do it on our videos and for customers where we do the installations we show you how to get consistent bobbin tension. Then we only have to adjust the top tension to get it in balance.

The training video below shows how we do this on our Handi Quilter longarm machines.

If you use a domestic machine with a top loading bobbin there is very little adjustment that you can make to the bobbin tension. The manufacturers sell this as a benefit for setting up the machine as they say that the tension is automatic. However, this is a disadvantage when you need to be in control of your bobbin tension!

For some domestic machines you can buy a special hook assembly to make adjustments possible. Most manufacturers don't generally show consumers how to adjust the bobbin tension for domestic top loading machines or even tell them if there is a different hook assembly. It's just not built to be used that way.

6. Industrial Needles and Needle Deflection

Our machines all use Industrial Needles. The machines run at fast speeds and with the industrial needle we get consistency, strength and they are excellent for multi direction free motion quilting.

With the very fast machines - 2500 stitches per minute or above you can also use multi direction needles called MR needles. They are even better for consistency when doing very fast stitching. You can read more about the MR needles on a separate blog post here.

If you use a domestic needle for your quilting you may be getting skipped stitches because the needle isn't designed to flex and bend at speed while the needle is in the work.

We use the same needles for cotton, polyester and metallic. So you don't need lots of different types of needles like you do for your domestic. We have needles for regular quilting (sharps), ballpoint needles for jerseys and knits (T shirt quilts mostly), the very fast machines (MR Sharps) and leather.

Comments

Post a Comment